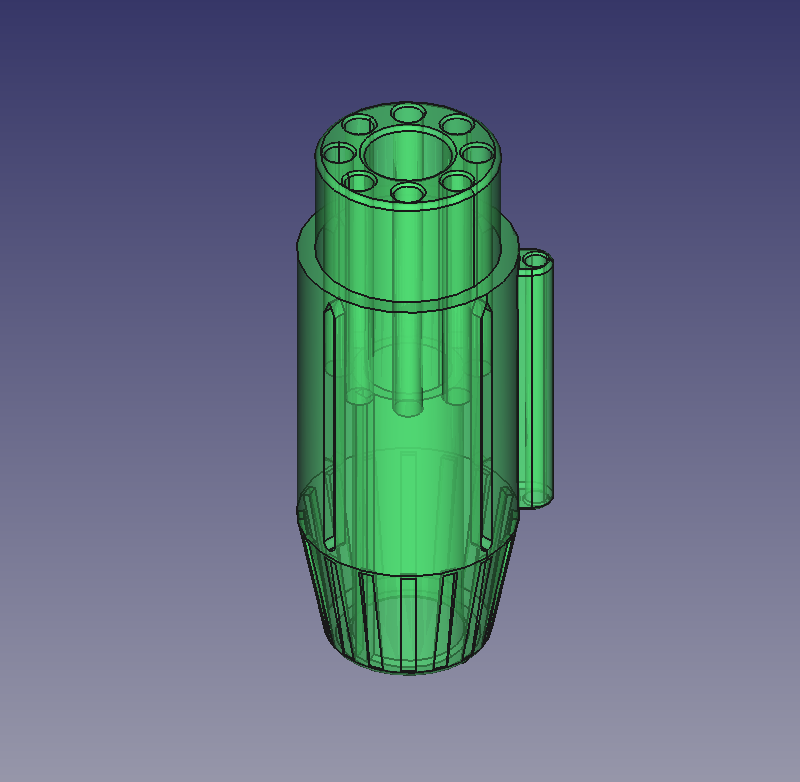

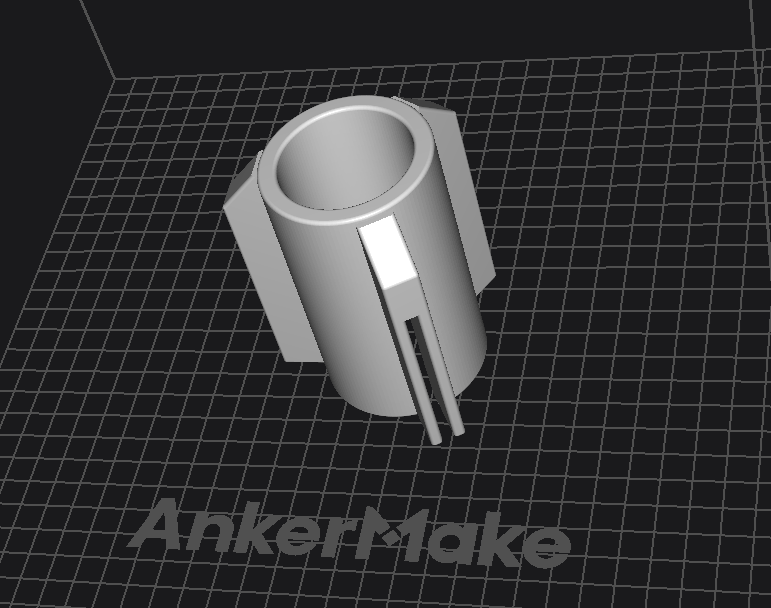

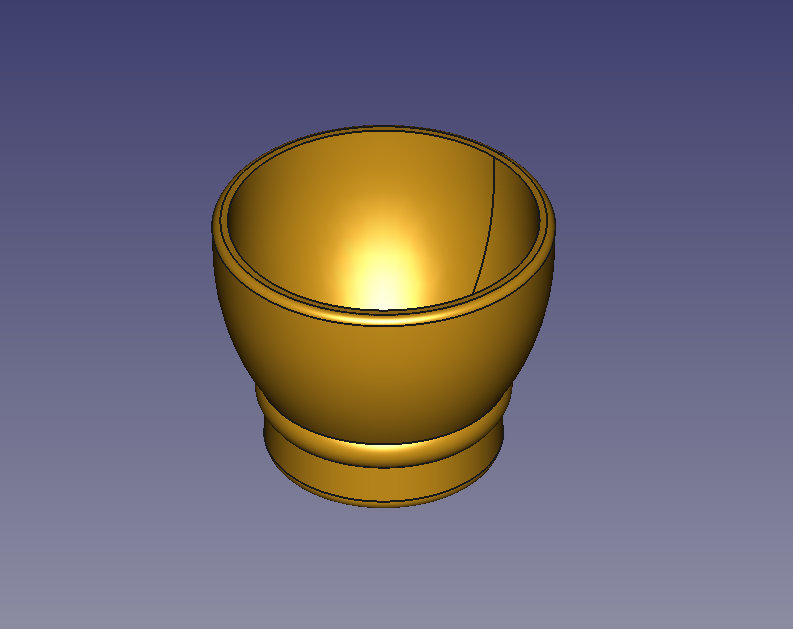

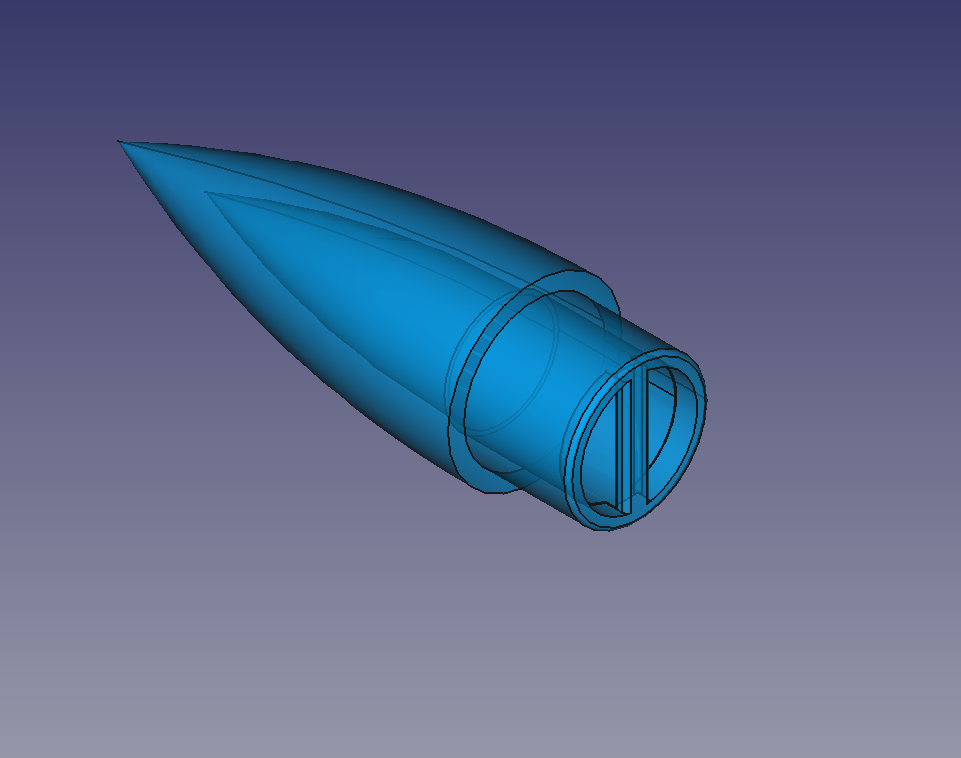

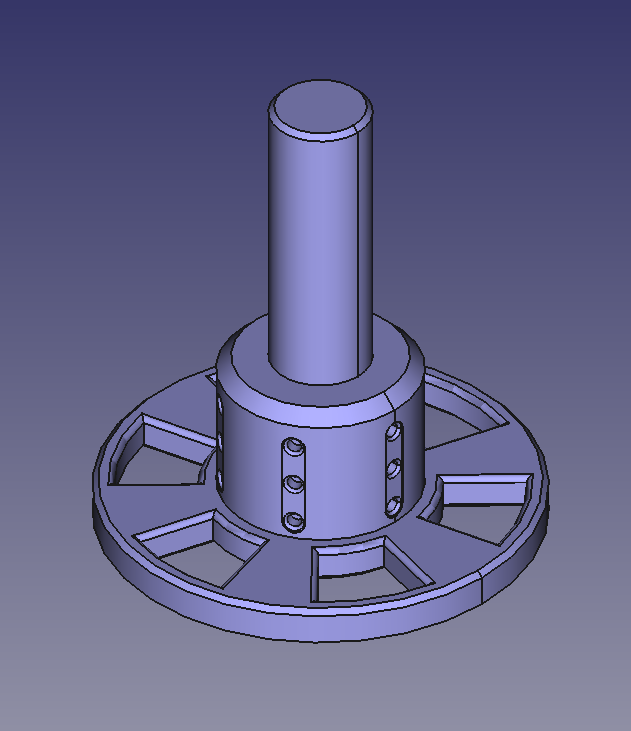

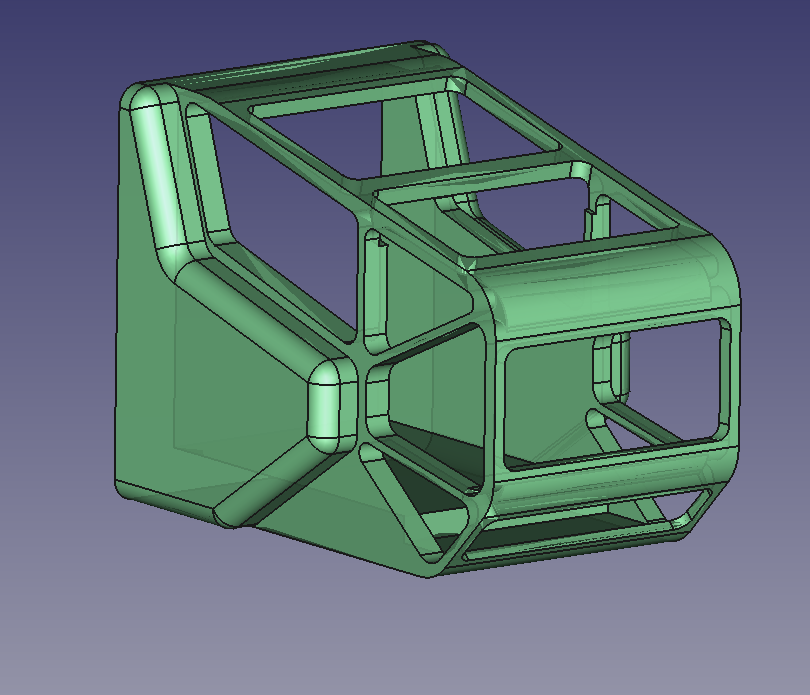

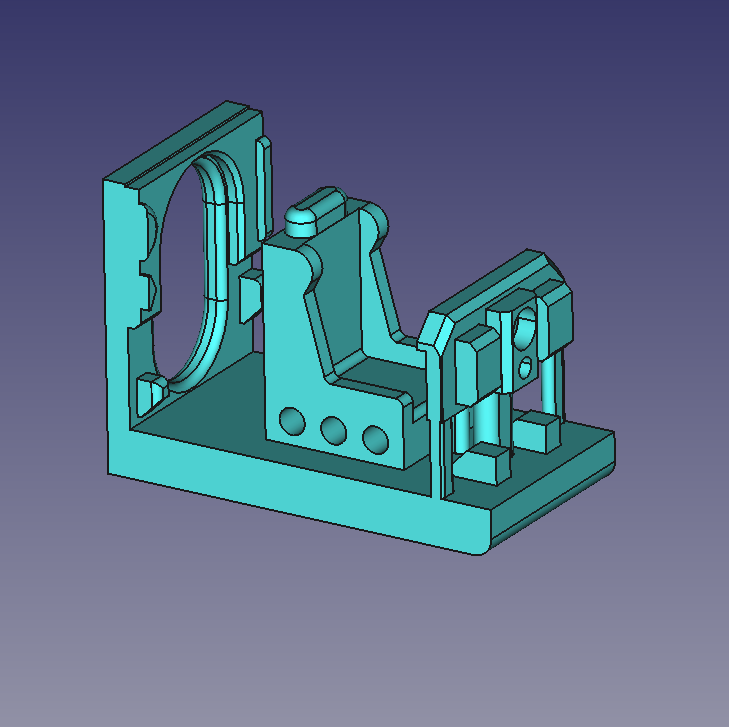

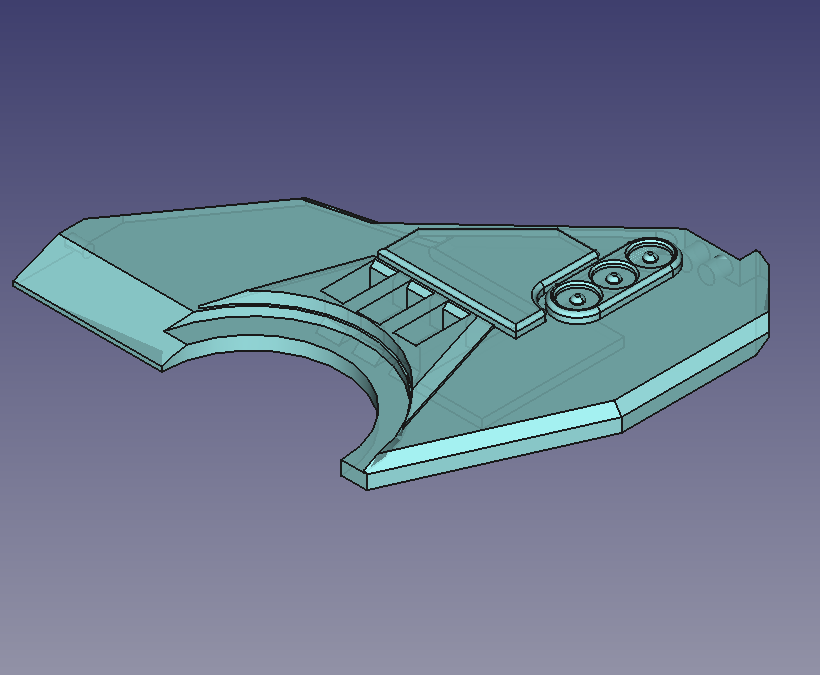

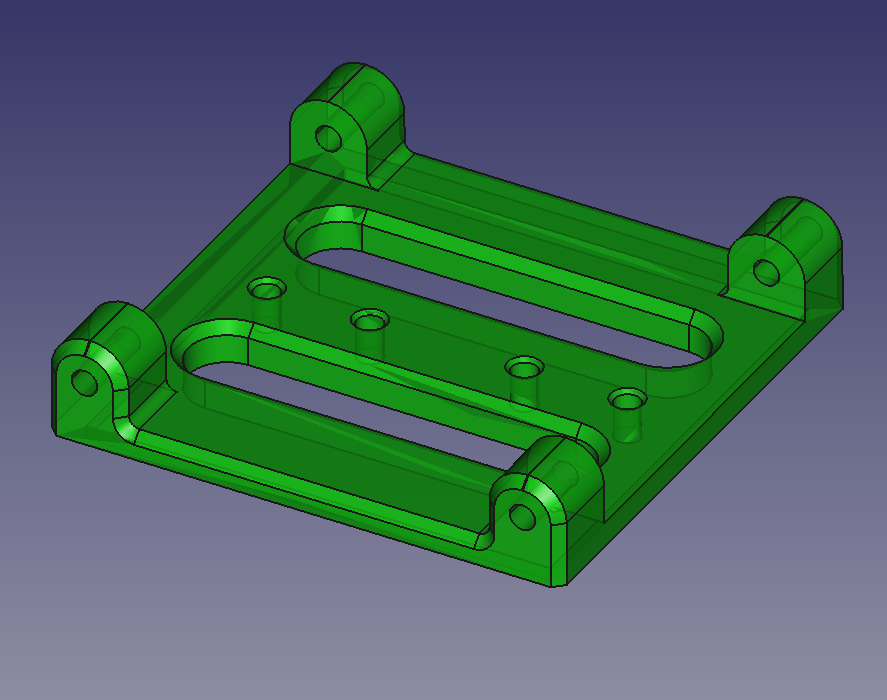

3D printers are rapidly becoming essential tools in model rocket design and parts manufacturing because they bridge the gap between concept and flight-ready hardware: designers can iterate complex nose cones, internal bulkheads, fin can geometries, and custom motor mounts directly from CAD files, print functional prototypes overnight, test-fit assemblies, refine aerodynamics and weight distribution, then produce final parts in durable materials — all without long lead times or expensive tooling. This workflow accelerates development, reduces cost for one-off or small-batch components, enables rapid troubleshooting and improvements after static tests or flights, and empowers hobbyists and professionals alike to transform a sketch or digital idea into a precisely fabricated part ready for assembly and launch.